Embrace speed, flexibility and quality with our cGMP Modular facility concept.

Our concept is based on independent, pre-engineered self-sufficient cleanroom modules with HVAC, electricity, utilities and embedded IoT.

15 years of pharmaceutical engineering experience combined with market knowledge from our partner SPgroups has been integrated into our smart modular concept.

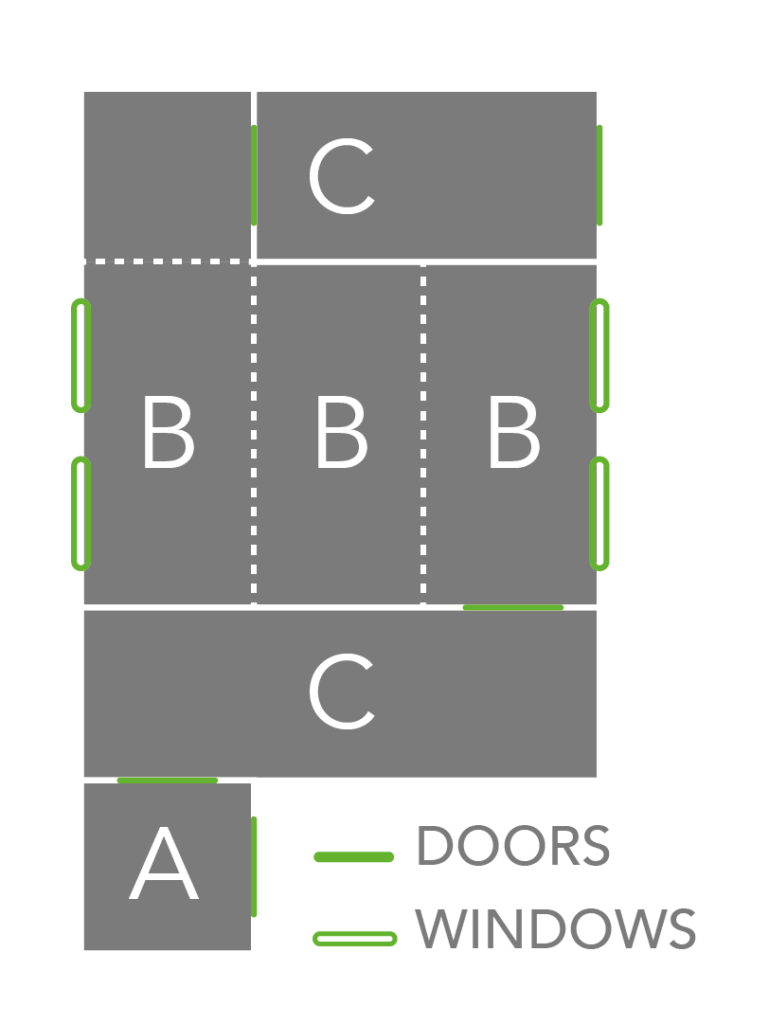

The structure has been designed in two distinctive parts: 1- Main module housing the cleanroom 2- Technical module placed atop the main module where ducting and utilities are fitted The structure was designed with specific dimensions and split into two parts to facilitate transportation to anywhere in the world. The position of external windows and doors is completely modular, allowing placement anywhere around the facility.

Our Module is designed for external installation. It is composed of a double skin: 1- External cladding – fully insulated and watertight and includes a guttering system 2- Internal skin – comprised of sandwich panels (fire resistant, insulated) for the cleanroom construction We can also modify the material type(s) to meet your project specifications (applicable regulations, project location, budget etc.).

The cleanroom is fully flushed and complies with ISO 14644-1 and cGMP standards. Inside the cleanroom module, we can achieve an ISO 5 to ISO 8 class (Grade B to D) depending on your requirements. We can reach this grade level due to our HVAC design, 2.7m clear height inside the cleanroom and an airtight construction. The cleanroom partition inside the module as well as the ceiling is completely modular, and can be modified to suit your needs.

Servers, EMS system, and HMI are embedded in the module. All sensors are connected to an IoT network enabling remote management from within an all-in-one web-based application. Track your performance and improve your business operations remotely.

HVAC system forms part of our modular solution and is key for achieving your desired cleanroom grade. We calculate and size the HVAC system in accordance with the number of modules to be fed and the expected grade wanting to be achieved (up to 50 exchange rate per hour). AHU is generally placed in a side shipping container and connected to the technical module. The modules come with pre-installed stainless-steel pipes and a distribution plate to supply utilities to the production area (WFI, pure steam, ice water, gas etc.).

From the modules comes your Smart Modular cGMP Facility.

3 module sizes to shape any type of life sciences facility

Our concept is based on three pre-engineered modules of 12, 24, 36 m2. They each have all the same height and width but different lengths.

Your facility is made by the assembly of these three smart pre-fabricated modules.

The modules are designed to allow for the maximum of possibilities:

-Full opening of any one side without the need for metal reinforcements when building a continuous cleanroom space.

-Stacking of up to 3 modules to accommodate height and equipment of large size

Standardization to speed up all phases of your project

We standardized the design across our three modules, facilitating manufacturing, enhancing quality and simplifying the supply chain. This simplification approach helps in reducing cost and accelerating the construction phase.

The validation phase is also easier and faster as once it is inspected by the regulatory authority, the module is no longer considered an unknown designed space.

Design, construction, and validation phases are completed faster, reducing time to market for your project.

Standardization does not prevent customization. Windows, doors, lighting, electrical appliances, filters, and utility plates can be placed anywhere within the cleanroom. Components such as airlocks; air showers; cart, hatch and window pass-throughs; as well as clean room furniture and gown rooms are all incorporated into the cleanroom module design.

Designed to keep your business running smoothly

Our modular concept limits disruption during any servicing or future modification.

The air handling unit, electrical room and black & white utility generator are separated from the cleanroom area, allowing services and maintenance to occur without interrupting operations.

Once commissioned, your facility is scalable or re-purposable.

Our double skin technology can be removed from the outside without compromising the existing cleanroom and without interrupting your business activity.

IoT and HMI are embedded allowing for the complete monitoring of your activities. This provides you peace of mind knowing that you can monitor and ensure that optimal conditions are still being met while any servicing or maintenance is taking place.

Designed to be deployed anywhere

Our Smart modules are self-sufficient, requiring only a concrete slab with evacuation piping and power supply to be fully operational.

Each module is both the controlled environment as well as the building itself.

Your modular cleanroom can be purposed as a permanent facility, or it can be used temporarily. This flexibility greatly reduces the risk of commissioning a new facility in a remote or uncertain location.

We can provide modular Vaccine production units, Cell/Gene therapy units, BSL2 laboratories etc…

If you would like to better understand how our modular concept works or are simply curious about how we could design your project to fit a modular construction …